Shaft Seal Chicago Pneumatic Screw Air Compressor 65*85*10 Oil Seal

Basic Info.

| Model NO. | 65*85*10 |

| MOQ | 1unit |

| Lead Time | Aroud 3-5 Working Days After Order Confirmed |

| Apply to | Screw Air Compressor |

| Transport Package | The Carton Packaging |

| Specification | 65*85*10 |

| Trademark | OEM |

| Origin | China |

| HS Code | 8421399090 |

| Production Capacity | 2000pieces / Month |

Product Description

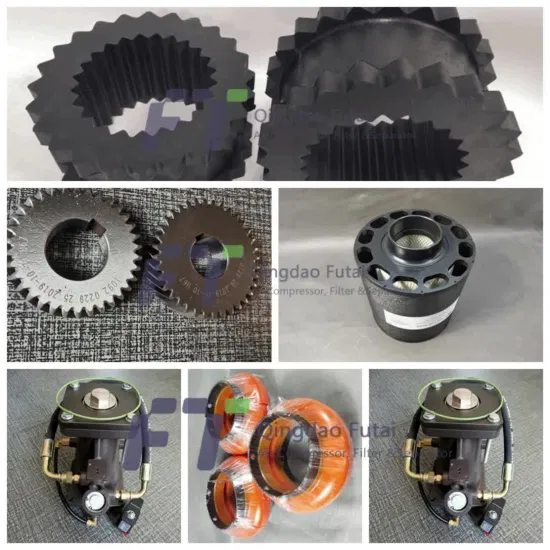

Shaft Seal Chicago Pneumatic Screw Air Compressor 65*85*10 Oil SealAir End Shaft Seal Kits Big range of various air compressor brands Airend Rebuilding kits and Shaft seal kits, we can even supply oil seal based on size Shaft seal is seal designed for the air screw compressors, and also for another devices which are operated in a heavy conditions, high pressure, temperature and chemically aggressive environment. Shaft seal housing is produced from the stainless steel, working surface is produced from PTFE

Design Features:

1.Dual PTFE lip

2.Reinforced sealing lip, Stianless Steel Ring

3.Resist deformation under more presure than single lip

4.Hydrodynamic return feed spiral groove for higher operational reliability

The main purpose of the shaft seal is sealing of the gap between the housing and leading screw of the air compressor. If compressor has gear transmission, the cuff seals electrical motor shaft. The housing of the shaft seal is produced from stainless steel. From the internal part of the seal there is elastic lips with high durability. They are designed for operation with high temperatures (to 250 °??) and pressure (to 25 bar). The air end rotation speed can reach 10000 rpm. Air end shaft seal can be produced also for more high pressures. More reliable air end sealing can be reached by the using the cuff with several rows of the sealing lips.

Operating Limits:

1.Temperature Range: -90 to +260 oC

2.Max. Pressure Load: 3 Mpa

3.Max. Peripheral Speed: 30m/s

4.Rotating In Same Direction: Anticlockwise/ Clockwise

Applications:

1. Suitable Media: Heat transfer fluids(oils), Air/oxygen, Reins/glues/pastes, Water/steam, Mineral-based & synthetic lubricants,Chemical waste water/wash water,corrosive/fluid/gaseous media, Powder/granulates, Foodstuffs

2.Typical Applications: Compressors, Pumps, Mixers, Actuators, Blowers, Strirring Systems..

Typical Sizes:

35*47*7

35*50*8

35*55*10

40*55*8

45*60*12

50*70*12

50*72*8

50*72*12

55*72*8

60*80*8

65*85*12

70*90*10

73*95*10

68*100*10

85*110*10

95*120*12

| Shaft Seal: |

Prevent the leakage of high pressure liquid from the pump and prevent air from entering the pump.Although the position of the shaft seal in the pump is not large, but the normal operation of the pump is closely related to the shaft seal.If the shaft seal is selected improperly, not only in the operation of the need for frequent maintenance, leakage of a lot of liquid is conveyed, and may be due to the leakage of flammable, explosive and toxic liquid caused by fire, explosion and poisoning accidents, the consequences are unimaginable.Therefore, the shaft seal structure must be selected reasonably to ensure the safe operation of the pump.

1.Due to the atmospheric pressure with the outside world in cylinder, will inevitably make steam in cylinder or cylinder outside air along the radial clearance between shaft and cylinder leakage or leakage into, thereby causing loss to the working medium, the deteriorating operating environment, and heating shaft neck or make the steam into the bearing chamber, causes the deterioration of oil, leaking into the air and vacuum, thus increasing the extraction load, the unit will reduce the efficiency,To this end, the rotor through the cylinder at both ends are equipped with a seal, the seal is called the shaft end seal for short.High pressure shaft seals are used to prevent the leakage of steam out of the cylinder, and low pressure shaft seals are used to prevent the leakage of air into the cylinder.

2.Steam turbine operation is bound to have a part of the steam leakage from the shaft end to the atmosphere, resulting in the loss of working medium and heat, but also affect the turbine generator working environment, if the improper adjustment of steam leakage is too large, will make the bearing near the shaft seal temperature rise or make the bearing oil water.For this reason, in all kinds of units, set up the shaft seal heater, in order to recover the steam turbine shaft seal leakage

3.Prevent the steam in the cylinder and stem leakage outward, pollution of the turbine room environment and bearing lubricating oil quality.During the normal operation of the unit, high temperature steam flows through the turbine shaft and makes it heated, thus causing overtemperature of the bearing.The vacuum part of the cylinder that prevents air from escaping into the cylinder.Ensure the vacuum effect and vacuum degree of condenser when the unit is started.Recover seal and stem leaks to reduce working medium and energy losses.

4.In the steam turbine brake shutdown and the condenser needs to maintain a vacuum during the whole hot state shutdown process, to prevent air leakage into the steam turbine, accelerate the steam turbine internal cooling, resulting in bending of the shaft.

| Company Profile&Certifications: |

| FAQ: |

A: Our products cover replacement hydraulic filter, Air compressor filters, Compressed air filter element, Heavy truck insert filters, Vacuum pump filters, and Some spare parts for compressors.

Q2. Is customized filter or OEM available?

A: Yes, just offer your required specifications and drawings.

Q3. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build new molds, but open new mold fee charged, when you place bulk order, the mold fee can return back.

Q4. What's your terms of packing?

A: Generally, we pack our goods in neutral boxes,outside brown carton cases. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q5. What's the terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balancing.

Q6. What's your terms of delivery?

A: (1)FOB (2)CFR (3)CIF.

Q7. How about your delivery time?

A: Generally, under MOQ quantity take 5-7 working days after receiving your advance payment. The specific delivery time depends on models and the quantity of your order.

Q8. What's your sample policy?

A: ,,,.