Stainless 316 Bonded Oil Seal Automotive Engine Parts Rubber Gasket Valve Stem Seal

Stainless 316 Bonded Oil Seal Automotive Rubber Parts Valve Stem Seal:1.We are professional RUBBER SEAL manufacturer and;

Basic Info.

| Model NO. | Bonded Seal |

| Free Samples | Yes |

| Delivery Way | Sea/Air/Express Delivery |

| Sample Lead Time | 3days |

| Size | Custom Accept |

| Certificated | RoHS/Reach |

| Color | Black/Brown/Orange/...etc |

| Storage Life | 10 Years |

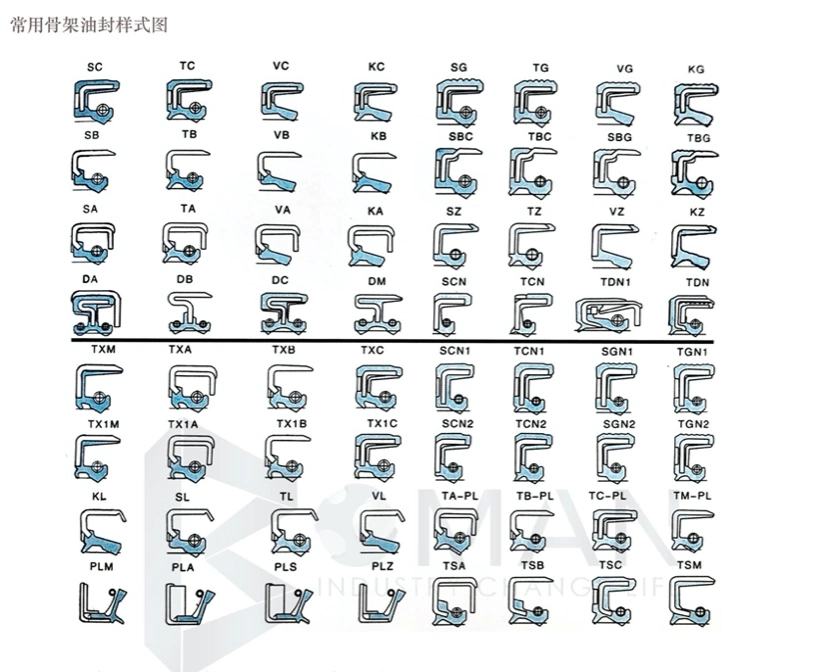

| Oil Seal Type | Tc/Sc/Tb...etc. |

| Transport Package | Bag |

| Specification | GB9877.1-88 |

| Trademark | Boman |

| Origin | China |

| HS Code | 4016931000 |

| Production Capacity | 200000PC/Month |

Product Description

Stainless 316 Bonded Oil Seal Automotive Rubber Parts Valve Stem Seal:1.We are professional RUBBER SEAL manufacturer and have more than 12 years export experience in different country.2.Have a strong technical team can customize rubber raw-material formula according to different needs.3.Factory have IATF 16949:2016 certificated and product with: KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA certificated.4.Have own mold department can finished mold process in very fast time and accept any high difficult mold.5.Have excellent quality and serving several global top 500 companies, can supply PPAP-3 Level documents.6.Have perfect After-Sales team, once cargo have problem will be 100% recall in the first time.

Bonded Seal Rubber Seal O Ring Molded Rubber Parts Rubber Oil Seal Product Details :

| OEM and ODM Are Also Welcomed | |||||||||||||

| 1.Raw-Material Brand: | DuPont (US) / Dow Corning (Germany) / Bayer (Germany) / 3M | ||||||||||||

| 2.Size: | We have more than 7000 size different rubber seal product mold in warehouse | ||||||||||||

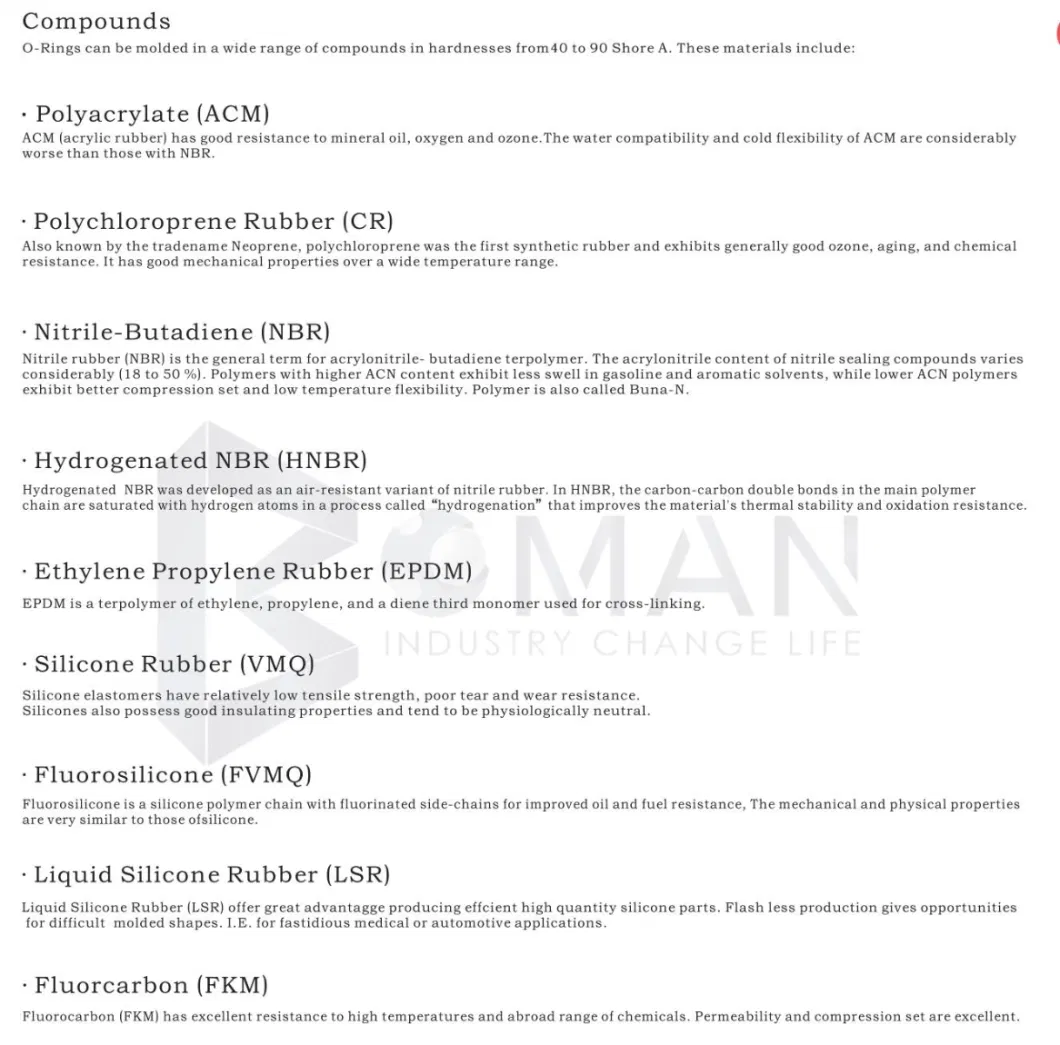

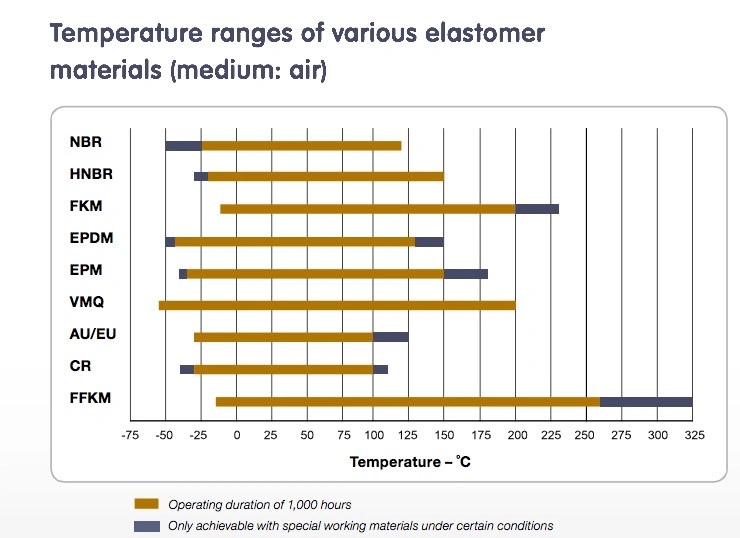

| 3.Material Type: | NBR / FKM / Silicone / EPDM / HNBR / ACM / Neoprene...etc. | ||||||||||||

| 4.Size Range: | ID from 0.5MM to 1.5M and customize size was acceptable in different products | ||||||||||||

| 5.Products Application: | Metallurgical, chemical, engineering, construction, mining, petroleum machinery and various types of instrumentation...etc | ||||||||||||

| 6.Color: | Black, white, red, green, or any customize | ||||||||||||

| 7.Parameters: | Temperature from -60° C to +220° C | ||||||||||||

| 8.Factory Certificate | IATF 16949:2016 certificated | ||||||||||||

| 9.Product Certificate | KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA | ||||||||||||

Factory Product Process Flow Chart:

| Steps | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | Note | ||||

| product | product | ||||||||

| 1 | Rubber material | visual | / | / | / | ||||

| 2 | IQC | Hardness tester | hardness | / | ★ | ||||

| Tensile machine | Tensile strength | / | / | ||||||

| Tensile machine | elongation | / | / | ||||||

| hydrometer | The proportion of | / | / | ||||||

| Aging test chamber | The compression permanent deformation | / | / | ||||||

| 3 | Mixing | mixer | / | Material thicknessmm | / | ||||

| 4 | IQC | rheometer | TS2 | / | / | ||||

| TS50 | / | / | |||||||

| TS90 | / | / | |||||||

| Hardness tester | hardness | / | ★ | ||||||

| 5 | Cutting edge /blanking | Cutting machine | / | Is long | / | ||||

| Material weight | / | ||||||||

| 6 | moulding | 300 t hot molding machine, automatic monitoring | / | The molding pressure (kgcm2) | ★ | ||||

| / | Molding time | ★ | |||||||

| / | Mold temperature | ★ | |||||||

| visual | appearance | / | / | ||||||

| Hardness tester | hardness | / | ★ | ||||||

| The projector/caliper | size | / | ★ | ||||||

| 7 | IPQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | ||||||

| The projector/caliper | size | / | ★ | ||||||

| 8 | deflashing | visual | appearance | / | / | ||||

| Automatic disassembly machine | / | speed | / | ||||||

| / | time | / | |||||||

| 9 | QC | Scissors/knife | appearance | / | / | ||||

| 10 | FQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | ||||||

| The projector/caliper | size | / | ★ | ||||||

| 11 | cleaning | Plastic basket | / | / | / | Manual cleaning | |||

| / | / | / | |||||||

| / | / | / | |||||||

| 12 | Post curing | The oven | / | time | ★ | ||||

| / | The temperature | ★ | |||||||

| 13 | Packing | Electronic says | Single - | / | / | ||||

| Baling press | The number of | / | / | ||||||

| The printer | The labe | / | / | ||||||

| visual | The cartons | / | / | ||||||

| 14 | OQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | ||||||

| The projector/caliper | size | / | ★ | ||||||

| visual | check | / | / | ||||||

| visual | weighing | / | / | ||||||

| 15 | Warehousing /delivery | transport cart | Delivery note | / | / | ||||

| Courier | / | / | |||||||

| Put in storage | / | / | |||||||

Factory:

Laboratory:

Certificated:

Why Choose BOMAN?1. We are professional RUBBER SEAL manufacturer and have more than 12 years export experience in different market.2. Have excellent quality and serving several global top 500 companies. 3. Have a strong technical team can customize rubber raw-material formula according to different needs. 4. Have perfect After-Sales team, once cargo have problem will be 100% recall in the first time. 5. Have own mold department can finished mold process in very fast time and accept any high difficult mold. 6. Factory have IATF 16949:2016 certificated and product with: KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA certificated.FAQ Q: What about your product MOQ?

A: Different product the MOQ was different, usually one size order amount match 150USD

Q: Supply OEM service?

A: Yes, we have OEM/ODM service

Q: What about your payment terms?

A: 30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo. Old customer no need advance desposit payment

Q: What about your order lead time?

A: Usually it was 15-20days finished order, if summer season due to high temperature the lead time need 30days

Q: What about your factory main business?

A: Our main product: OIL SEAL, O RING, BONDED SEAL, RUBBER STRIP, GASKET, CUSTOMIZE RUBBER PARTS...etcQ: Can you supply free samples?

A: Yes, once order make sure we can supply free samples and afford delivery cost

Q: What about product HS code?

A: 4016931000 and 84879000 it was mainly use by our customer.

You may also like

Send inquiry

Send now